SPC Floor Production Line

Lisebelisoa

Setsi sa senotlolo sa spc se entsoe ka polyvinyl chloride (e arotsoe ka thepa e ncha e hloekileng, lisebelisoa tse tsoakiloeng, lisebelisoa tse tsosolositsoeng), phofo ea calcium (e thathamisitsoeng ka sehlopha sa phofo ea majoe) le solvent (ts'ebeliso ea lik'hemik'hale tsa lik'hemik'hale le tsona li sebelisa kereiti ea lijo tsa limela).

Ho sebetsa

Mokhoa oa 1: ho kopanya

Methara e ikemetseng ho latela karo-karolelano ea thepa e tala → motsoako o chesang oa motsoako o phahameng haholo (mocheso oa motsoako o chesang: 125 ℃, Ke ho

kopanya mefuta eohle ea lisebelisoa ka ho lekana, tlosa mongobo ka har'a lisebelisoa) → kenya motsoako o batang (folisa lisebelisoa, Thibela

kaka le ho feto-fetoha ha 'mala, mocheso o batang oa ho kopanya: 55 ℃.) → kopanya ka ho lekana ka ho pholisa;

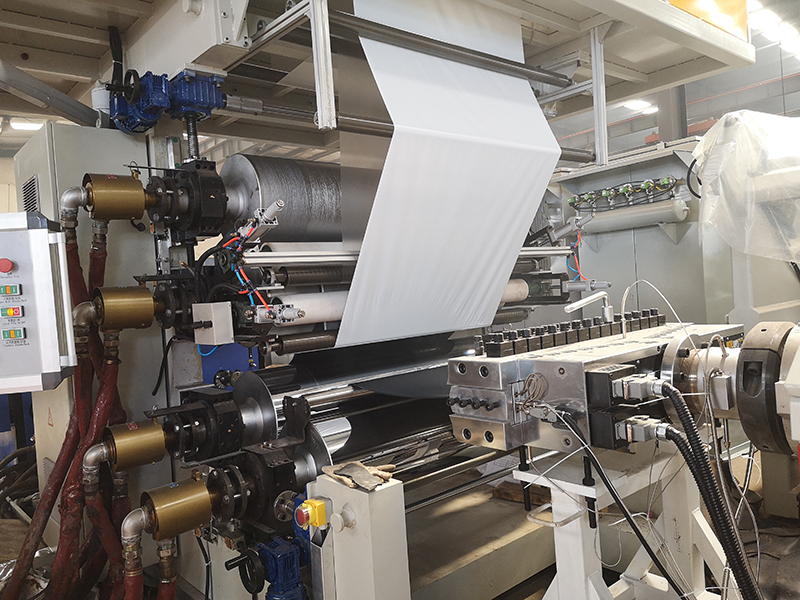

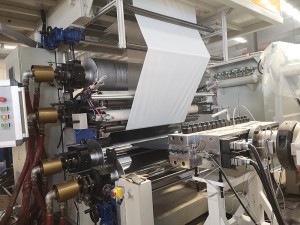

Mokhoa oa 2: extrusion

mafahla-screw extruder bakeng sa ho futhumatsa extrusion → kenya lakane shoa hlooho bakeng sa extrusion bōpa, ho etsa lakane. Kamora tse nne

k'halendara ea roller, thepa ea motheo ke botenya bo tsitsitseng → filimi ea mebala → apara lesela → ho pholile → ho itšeha;

Mokhoa oa 3: Ho futhumatsa UV

Sebaka sa UV → ho futhumatsa (mocheso oa metsi a chesang: 80 ~ 120 ℃; mocheso oa metsi a batang: 10 ℃)

Mokhoa oa 4: ho phunya le ho roala ho paka

Ho seha → ho petla, ho poma le ho khahleha → ho hlahloba → ho paka

Lenane la Mechini

Karolo ea Extrusion

| Che. | Lebitso la Mochini | Bongata |

| 1. | Mochini o Kopanyang Bakeng sa PVC le phofo ea Calcium | 1 sete |

| 2. | Mochini oa ho Fepa Bakeng sa Mochini o Kopanyang | 1 sete |

| 3. | Mochini o Ikemetseng oa ho Fepa Bakeng sa Extruder | 1 sete |

| 4. | SJSZ 92/188 Conical Twin Screw Extruder | 1 sete |

| 5. | Mold le Die tse bōpehileng joaloka T | 1 sete |

| 6. | Khalendara ea meqolo e mene | 1 sete |

| 7. | Foreimi e Pholisang | 1 sete |

| 8. | Sete ea ho Trimming | 1 sete |

| 9. | Sesebelisoa sa ho Hōlisa | 1 sete |

| 10. | Mochini oa ho itšeha o iketsang | 1 sete |

| 11. | Karolo ea Stacking | 1 sete |

Melemo:

a.zero benzene le formaldehyde, ha e na sekhomaretsi le ntho e chefo, 'me e ka sebelisoa hape ka 100%;

b.stable perforance: ha ho na ho phunyeha, ha ho na katoloso, ha ho na deformation, ha ho tlhokomelo le tlhokomelo, ho bonolo ho hloekisa, ho boloka litšenyehelo tsa tlhokomelo le ho lokisoa hamorao.

c.Bopaki ba metsi le bopaki ba mongobo. e ka sebelisoa sebakeng seo lihlahisoa tsa lehong tsa setso li ke keng tsa sebelisoa;

d.e thibelang mollo: tekanyo ea mollo oa B1 boemo;

e.thibela likokoanyana, bohloeki-bopaki, antibacterial lebatooa le lecha;

f. phello e ntle ea ho monya molumo: ho fihla ho 20dB e loketseng libaka tse kang: sepetlele, laeborari;

g. ho kenya habonolo: tsamaiso ea senotlolo sa ho koala ka bobeli kapa ka morao e omeletseng e lokile;

h.colorful wood grain mokhabiso filimi ho khetha ho tloha le hammoho le embossing pattern, the SPC flooring e fana ka ponahalo ea lehong le lehong le amang maikutlo.